Capability management is also essential to business organizations that seek to maximize resources, fulfill demand, and establish working efficiencies. Whether in a manufacturing facility or as a project manager of a remote team, the effective implementation of a capacity planning plan will help you avoid being either overcommitted or overresourced.

What is Effective Capacity Planning?

Effective capacity planning refers to the calculation of the volume of production that an organization requires to meet varying fluctuations in demand for its products or services. It entails the study of resource stocks, future estimates, and planning in line with the operations. Effective capacity planning involves the use of forecasting, flexibility, and real-time data, unlike simple capacity estimation.

The significance of Capacity Planning in the Management of Operations

Workload forecasting is crucial in operations management to enable an organization to match its supply with demand. It eliminates shortages of resources and bottlenecks in production, hence guaranteeing customer satisfaction and profitability. Poor capacity planning may leave companies to either underutilize resources or fail to supply the market demands.

What it Takes to Become Successful in Capacity Planning

Some of the best Workload Forecasting strategies that companies should employ are

- Lead Strategy: Adding capacity to meet a forecasted demand.

- Lag Strategy: Adding capacity with demand that is proven.

- Match Strategy: Gradually expanding capacity with the increase in demand.

- Adjustment Strategy—Adjustment in terms of increasing or reducing the capacity by current information.

The strategies should also be specific in terms of industry, variability of demand, and the available resources.

Actions in Effective Capacity Planning

These are important steps to implementing successful workload forecasting:

- Projection of demand. The future demand can be forecasted using the following formula:

- Hoisting up the existing capacity

- Finding gaps in capacity

- Creation of a resource plan

- Putting together and overseeing the plan

These actions will guarantee a dynamic business adaptive to the changes taking place in the market.

Capacity planning forecasting

Workload forecasting involves forecasting based on historical data and the market and using predictive behavior to predict future demand. All of these can enhance capacity planning: time series analysis, regression modeling, and the AI-based forecast.

What is resource capacity planning?

Resource Workload forecasting is concerned with resources, especially human and technological, as well as their allocation. Capability planning is the key to ensuring that an organization does not get burned out and underperform by careful staffing and proper workloads.

Project Management and Capacity Planning

Workload forecasting is effective in the management of projects so that managers can adjust the capacity of a team to the needs of a project. This includes:

- Distributing members of the team based on skill and availability.

- Avoiding Overassignments

- Make sure there is promptness in the delivery of milestones.

This makes the usage of resources maximized without delays in projects.

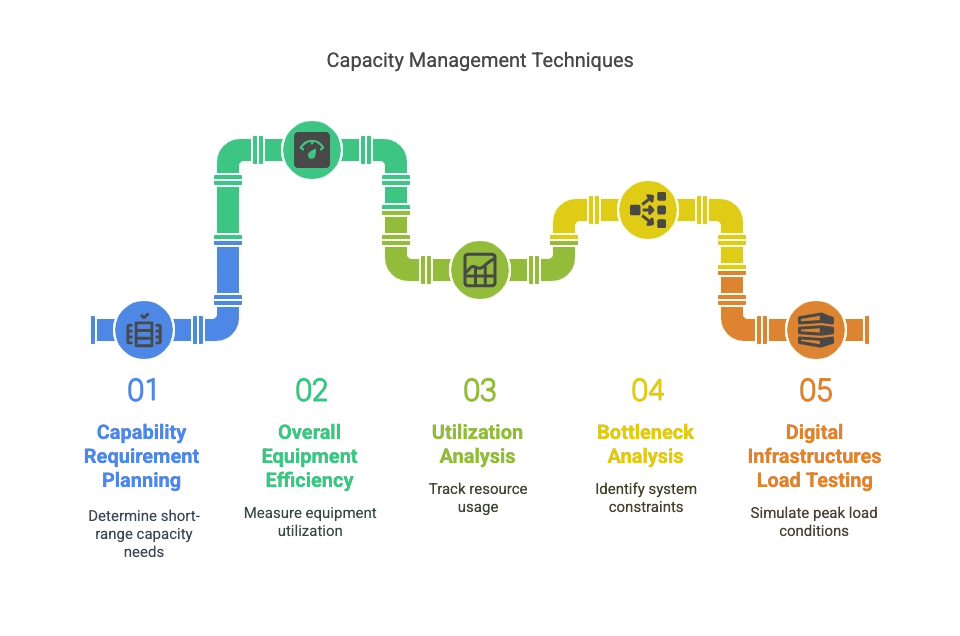

Techniques of Capacity Management:

There are many approaches to capacity management that businesses may apply, such as

- Capability requirement planning (CRP).

- General Equipment Efficiency (OEE).

- Utilization Analysis

- Bottleneck Analysis

- Digital Infrastructures Load Testing

The methods are useful in decision-making, as they determine the weak points and improve them in terms of their throughput.

Tools of Capacity Planning by Managers

Contemporary means facilitated the data-driven and efficient workload forecasting. The best tools include

- Smartsheet—to see the workloads.

- Toggl Plan is perfect for tracking the capacity of the team.

- Plaky is resource planning software and project management software.

- Microsoft Project is powerful software to control the huge project capacity.

- Tivazo: To monitor the time and work of teams.

These resources help in an easier process of forecasting, allocating, and adjusting resources.

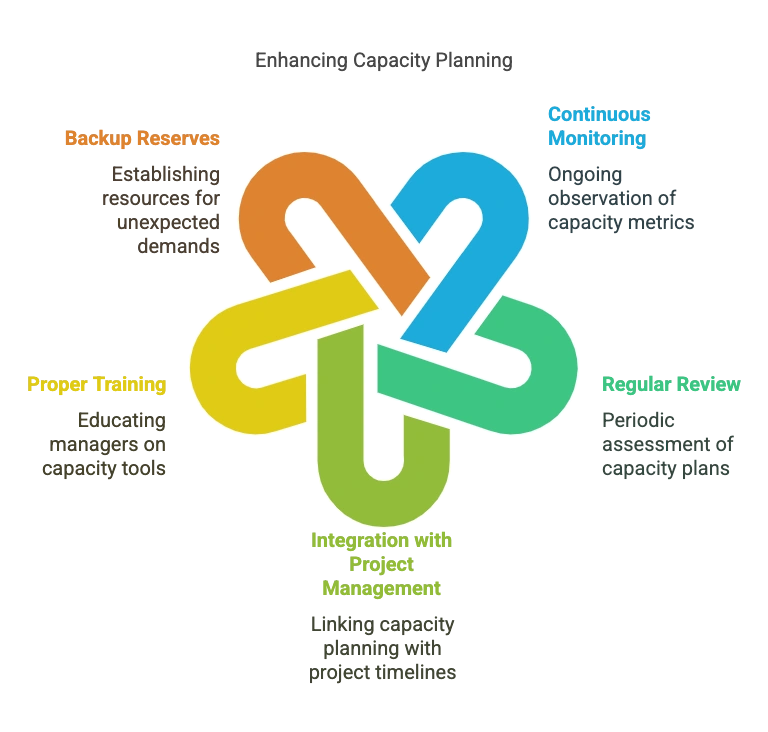

Best practices of capacity planning

The top practices that can be adopted to make capacity planning successful include the following:

- Forecasts should be revised regularly (with real-time data)

- Review the capacities every quarter

- Connect with project management systems

- The capacity tools to be trained on by managers

- Establish backup reserves in case of unanticipated demand

Adherence to these practices guarantees more comfortable working processes and fewer conflicts over resources.

The Capacity Planning of Service Industries

Proper workload forecasting is equally vital even in the service industries such as healthcare, education, and IT support.

For example:

- It is used by hospitals to have the exact number of beds and personnel.

- In call centers, forecasting is an instrument to schedule operators.

- Educational facilities arrange the classrooms and faculty workloads.

In this type of environment, customer experience is based on controlled forecasts and alignment to capacity.

Real-life examples of Capacity Planning

- Amazon: Predictive analytics with its warehouse delivery capacity.

- Toyota uses lean in planning its manufacturing capacity.

- Netflix scales the servers according to the audience patterns.

- Airlines: Depending on the bookings, adjust crew availability and seat availability.

The above illustrates how useful capacity planning can be in enhancing operational flexibility and profitability.

Effective Capacity Vs Actual Capacity

The most important idea is to know the distinction between actual and effective capacity:

- Actual capacity is the total possible output under ideal circumstances.

- Effectively, the realistic production is given constraints such as maintenance and employee breaks.

Effective workload forecasting reduces the risk of overestimation of an organization and enables it to plan more realistically.

Solving Problems of Capacity Planning

Challenges:

- Improper demand estimates

- Shortage of resources

- Failure to see through all teams

Solutions:

- Apply AI-based forecasting

- Adopt cross-functional planning tools

- Keep flexible personnel and production plans

These are solutions that boost the success of effective workload forecasting.

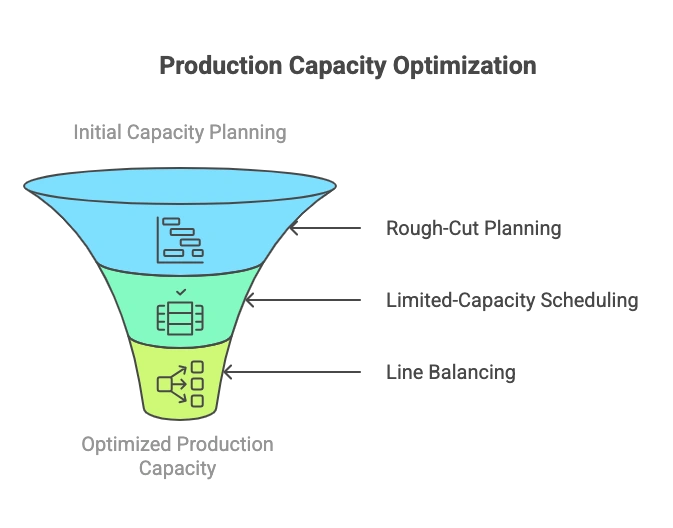

Strategies of Production Management on Capacity Planning

The workload forecasting methods that are crucial to production management include

- Rough-cut capacity planning at the initial stage.

- Scheduling of limited-capacity production.

- Line balancing apportions the workloads evenly.

These provide the smooth flow of production with minimal stoppage and waste.

The conclusion.

Effective workload forecasting goes beyond a tactical need; it is a strategic benefit. It is also possible to facilitate businesses’ long-term and sustainable growth by deploying effective capacity planning techniques, using sophisticated tools, and responding to demand through intelligent forecasting. In projects, operations, or services, capacity planning has to be effective so that the resources are utilized, employees are involved, and customers are satisfied.

The importance of good capacity planning cannot be underestimated, and from spotting the gaps in capacity to deploying scalable measures, capacity planning is important. Organizations that learn to manage it will become role models in terms of productivity, performance, and profitability.